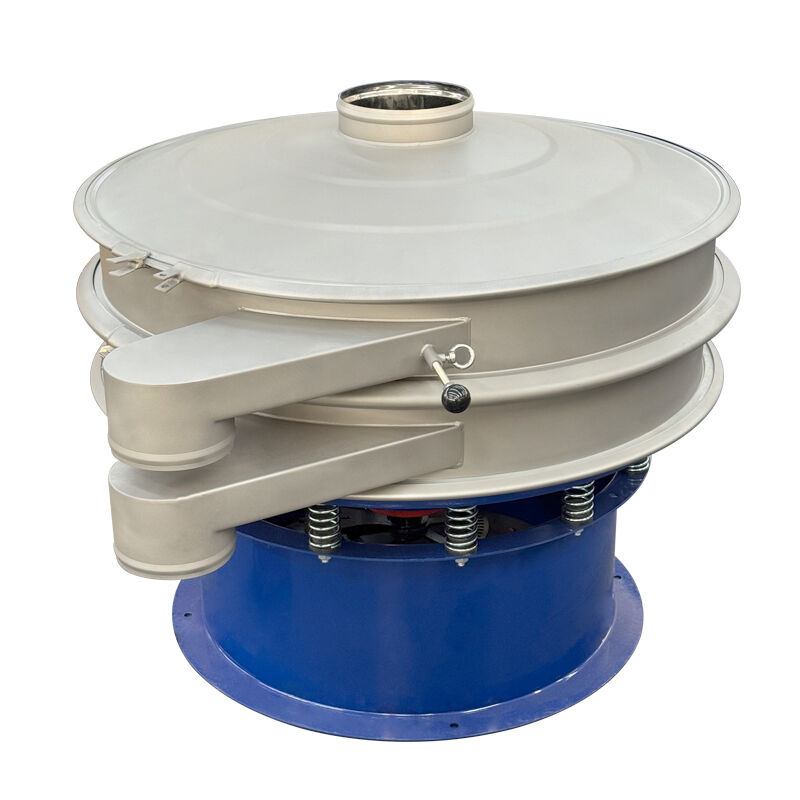

Vibratory Screening Machine

Product description

The rotary vibrating screen is a highly efficient and versatile fine screening equipment. It is characterized by a cylindrical closed structure, which effectively prevents dust from escaping. This equipment features a multi-layer screen design, enabling the precise separation of materials into multiple particle size grades in one go. It is widely used in the particle classification, powder sieving, and slurry filtration in fields such as chemical engineering, food, and metallurgy. Its core advantages lie in high screening accuracy, large processing capacity, smooth operation, and ease of cleaning and maintenance. It can be flexibly adjusted according to the characteristics of different materials, and is one of the key equipment for achieving efficient separation in modern production.

Working principle

The working principle of the rotary vibrating screen is based on its core power source - the vertical vibration motor. At both ends of the motor shaft, adjustable eccentric weights are installed. When the motor rotates at high speed, the centrifugal forces generated by the two weights combine to form a unique three-dimensional rotary vibration force.

This force is transmitted to the entire sieve body, causing a complex combined vibration on the surface of the sieve mesh. The material does not move in a straight line on the sieve surface; instead, it follows a gradually increasing spiral trajectory: finer particles have more opportunities to pass through the sieve holes vertically, while coarser particles are rapidly transported along the spiral trajectory to the discharge outlet at the edge.

By adjusting the phase angle of the eccentric weight through physical means, the vibration trajectory and intensity can be easily changed, thereby precisely controlling the diffusion speed, retention time and movement mode of the materials on the sieve surface, to meet various process requirements ranging from fine screening to rapid filtration. The entire process is efficient, continuous, and the sieve separation accuracy is extremely high.

Features & Benefits

1.High precision and high efficiency

The three-dimensional rotary vibration mode enables the materials to rapidly spread and pass through the screen, with strong anti-blockage capability and high screening accuracy.

2. Multi-layer synchronous classification

Configurable multi-layer screens enable multiple particle size specifications to be produced in a single run, saving space and energy consumption.

3. Fully enclosed and environmentally friendly

The sealed design prevents dust from spilling out, meeting the requirements for cleanliness, explosion-proofing, and the production of special materials.

4. Flexible adjustment and strong adaptability

By adjusting the eccentric block, the screening trajectory and intensity can be changed, enabling it to adapt to various working conditions such as dry and wet screening, filtration, etc.

5. Durable and easy to maintain

The structure is sturdy, the sieve mesh can be replaced easily, it is convenient to clean, and it is suitable for long-term continuous operation.

6. Smooth operation and economical

Good power balance, low noise, easy installation, and low overall operating cost.

Product parameter

| Model |

Equipment diameter |

Power(KW) |

Deck |

Effective screening area(m2) |

Screen mesh |

| EXZS-600 |

600mm/24inch |

0.25 |

1-5 |

0.2289 |

20 microns to 20 mm |

| EXZS-800 |

800mm/32inch |

0.55 |

0.4183 |

| EXZS-1000 |

1000mm/40inch |

0.75 |

0.6359 |

| EXZS-1200 |

1200mm/48inch |

1.1 |

0.9499 |

| EXZS-1500 |

1500mm/60inch |

1.5 |

1.5386 |

| EXZS-1800 |

1800mm/70inch |

3 |

1-4 |

2.2687 |

| EXZS-2000 |

2000mm/78inch |

4.5 |

2.8893 |

Production line diagram

1. Vacuum feeding into the mixer, automated, dust-free

2. The mixed materials directly enter the sieve machine for screening

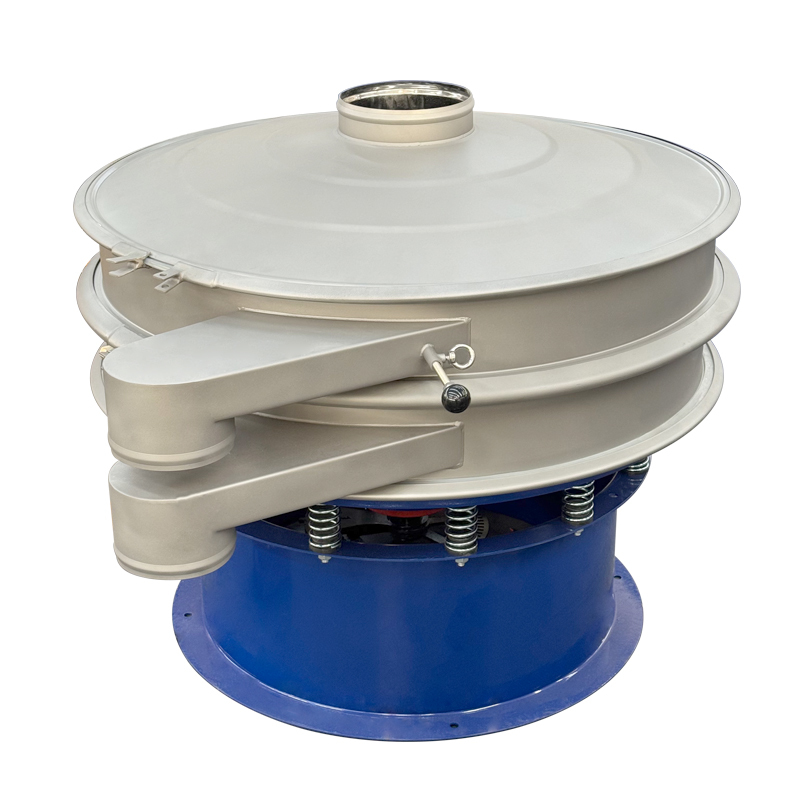

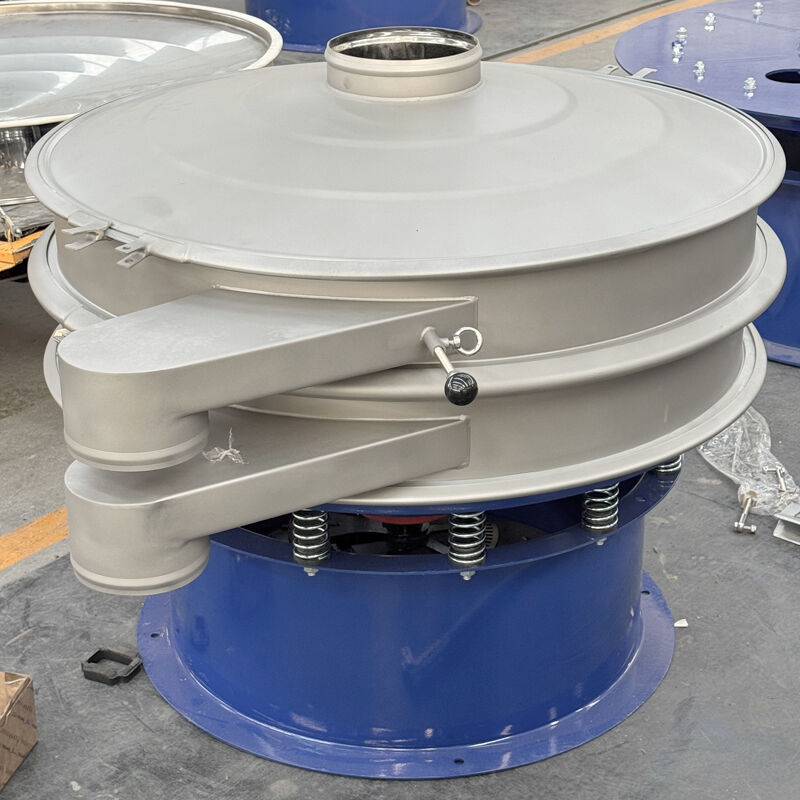

Detail display

Application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer, Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries. We welcome customers or dealers to visit our factory and will arrange everything for you.Our factory address: West of the industrial and commercial office of Da Zhaoying Town, Xinxiang City, Henan Province.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!